Destructive Attribute MSA (Measurement System Analysis) PDF PDF Forum Government

1. How much the measurement system reduces the strength of a signal (out of control point) on a control chart. 2. The chance of the measurement system detecting a large shift. 3. The ability of the measurement system to track process improvements. These three insights give you a very good understanding of the relative usefulness of the.

(PDF) Combination VIKOR Model and Measurement Systems Analysis (MSA)

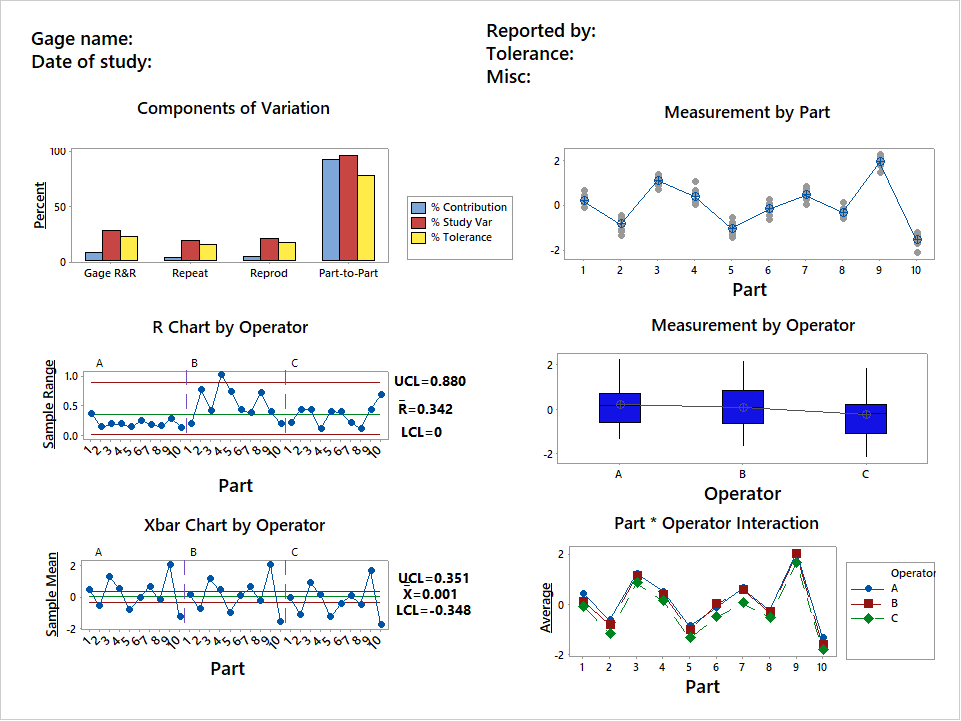

measurement system analysis (MSA), we use statistical methods to estimate how much of the total study variation (SV) is due measurement system. An ideal measurement system should not have any variation. However, this is impossible and we have to be satisfied with a measurement system that has variation less than 10% of

Measurement Systems Analysis (MSA)

Scope. 1.1 This guide presents terminology, concepts, and selected methods and formulas useful for measurement systems analysis (MSA). Measurement systems analysis may be broadly described as a body of theory and methodology that applies to the non-destructive measurement of the physical properties of manufactured objects.

Measurement System Analysis (MSA) Part 2 YouTube

Measurement system analysis (MSA) is a set of procedures which are used to determine the amount of variation due to the measurement system and if the measurement data are valid.

MSA Measurement System Analysis QualityOne

Measurement System Analysis Made Easy. With measurement system analysis (MSA), measurement processes can be enabled and optimised. To do this, the user must identify the relevant influencing factors of the MSA, reduce standard deviation and systematic measured value deviation. An X-ray fluorescence measuring instrument offers excellent.

MSA What is Measurement Systems Analysis? Examples

"Measurement Systems Analysis" (MSA) for Semiconductor Process Control Doug Sutherland, Ph.D. David W. Price, Ph.D. Jay Rathert Ian O'Leary. 2 Twenty-First Annual Automotive Electronics Council Reliability Workshop, April 30 - May 2, 2019 Agenda 1. Introduction 2. Metrology Measurement Systems 3. Defect Inspection Measurement Systems

What is MSA? Measurement System Analysis Gauge R&R Repeatability Quality (QA/QC) with

MSA is a collection of experiments and analysis performed to evaluate a measurement system's capability, performance and amount of uncertainty regarding the values measured. We should review the measurement data being collected, the methods and tools used to collect and record the data. Our goal is to quantify the effectiveness of the.

MSA Measurement System Analysis in accordance with AIAG and VDA 5 requirements training for

The purpose of a measurement system analysis is to determine the capability of the measurement process as well as determining its sources of variation and its behavior within the range of application. It is often used as an effective way of selecting a measurement process and equipment (instruments, gauges) and provides a basis for comparing.

MSA Measurement Systems Analysis MSA 4th Ed PDF

Measurement System Analysis (MSA) with attribute data in a leading automotive industry assembly line. Keywords: Repeatability , Reproducibility .Truth table 1. INTRODUCTION MSA is a tool used to evaluate the statistical properties of process measurement system (Srinivasan J. 2000). The purpose of MSA is to statistically verify that

Measurement System Analysis (MSA) DreamEDGE System... · Measurement System Analysis (MSA

Measurement system analysis (MSA) is a procedure used to assess the capability of a. measurement system by quantifying the variation of the method used for taking measurements. MSA is widely used.

PPT Measurement System Analysis (MSA) PowerPoint Presentation, free download ID1185802

Measurement System Analysis (MSA) ensures consistent quality of the manufacturing process and ensuring accuracy of the test measurement readings collected. A manufacturing process setup in this manner, will prevent debug time, rework labor, scrap, lost capacity, degradation of DUT due to unnecessary retest, missing planned shipments etc. In.

MSA Pro Measurement System Analysis Software Gage Management

Understanding Measurement System Analysis (MSA) also .. (2010), Measurement Systems Analysis Reference Manual (4 th ed.), AIAG, Detroit, MI. 3. MINITAB 17, Statistical Software Package. R e f e r e n c e 0 .4 2 6 8 M e a n 0 .4 2 6 8 6 1 6 7 S t D e v 0 .0 0 0 2 0 2 5 7 1

(PDF) CARRYING OUT OF MEASUREMENT SYSTEM ANALYSIS (MSA) ON OJSC «BSW MANAGEMENT COMPANY OF

The manual should be considered and introduction to measurement system analysis. It is not intended to limit evolution of analysis methods suited to particular processes or commodities. While these guidelines are intended to cover normally occurring measurement systems situations, there will be questions that arise.

MSA Explained 2023 Guide

Measurement System Analysis Robert Schmitta* and Marcin Bauzab aMetrology and Quality Management, Laboratory for Machine Tools and Production Engineering WZL of the RWTH, Aachen University, Aachen, Germany bChair of Metrology and Quality Management, Carl Zeiss Industrial Metrology, Maple Grove, MN, USA Synonyms Measurement systems analysis; Measurement systems capability analysis; MSA

AIAG Measurement Systems Analysis MSA Hardcopy Manual LMR Global

MSA (Measurement System Analysis) methods are widely used in various industries in order to identify and assess extra variation (noise) generated in manufacturing process control and product inspection by a selected measurement system, This variation, i.e. measurement errors, if not controlled, may result in false decisions.

Measurement System Analysis (MSA) Online Blended eLearning Course

The purpose of a measurement system analysis is to determine the capability of the measurement process as well as determining its sources of variation and its behavior within the range of application. It is often used as an effective way of selecting a measurement process and equipment (instruments, gauges) and provides a basis for comparing.

.